D51EX-22

Specifications

ENGINE

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Komatsu SAA6D107E-1*

Type. . . . . . . . . . . . . . . . . . . . . . 4-cycle, water-cooled, direct injection

Aspiration . . . . . . . . . . . . . . . . . . . Turbocharged, air-to-air aftercooled

Number of cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Â

Bore x stroke . . . . . . . . . . . . . . . . . . 107 mm x 124 mm

4.21" x 4.88"

Â

Piston displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.69 ltr

408 in3

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . All-speed, electronic

Horsepower

Â

SAE J1995 . . . . . . . . . . . . . . . . . . . . . . . . . . . Gross 99 kW

133 HP

Â

ISO 9249 / SAE J1349 . . . . . . . . . . . . . . . . . . . Net 97 kW

130 HP

Â

Hydraulic fan at maximum speed . . . . . . . . . . . Net 90 kW

120 HP

Rated rpm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2200 rpm

Fan drive type . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic (reversible)

Lubrication system

Method . . . . . . . . . . . . . . . . . . . . . . . . Gear pump, force lubrication

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full-flow

*EPA Tier 3 emissions certified

HYDROSTATIC TRANSMISSION

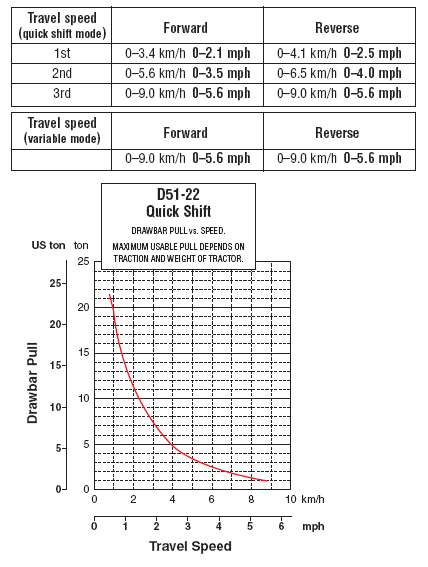

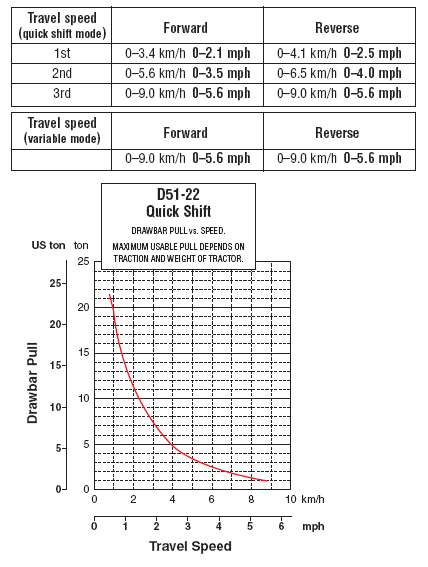

Dual-path, hydrostatic transmission provides infinite speed changes up to 9.0 km/h 5.6 mph. The variable capacity travel motors allow the operator to select the optimum speed to match specific jobs.

Travel control lock lever and neutral switch.

Final Driver

Â

Two-stage planetary gear integrated into axial piston travel motors. Compact in-shoe mount reduces risk of damage by debris. Bolt-on sprocket segments for easy replacement.

Coolant and Lubricant

| Coolant |

35 ltr 9.3 U.S. gal

|

| Fuel tank |

270 ltr 71.3 U.S. gal |

| Engine oil |

20 ltr 5.3 U.S. gal |

| Hydraulic tank |

63 ltr 16.6 U.S. gal |

| Final drive (each side) |

4.0 ltr 1.1 U.S. gal |

OPERATING WEIGHT (APPROXIMATE)

Â

Tractor weight:

Including ROPS cab, rated capacity of lubricant, coolant, full fuel tank, operator, and standard equipment.

D51EX-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11220 kg 24,736 lb

D51PX-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11620 kg 25,618 lb

Operating weight:

Including power angle tilt dozer, ROPS cab, operator, standard equipment, rated capacity of lubricant, coolant, and full fuel tank.

D51EX-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12720 kg 28,043 lb

D51PX-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13220 kg 29,145 lb

Dozer Equipment

.jpg) Â

Â

Standard Equipment For Base Machine

ENGINE AND RELATED ITEMS

• Air cleaner, dry, double element type with caution lamp on monitor

• Decelerator pedal

• Engine, KOMATSU SAA6D107E-1, net output of 97 kW 130 HP direct injection, turbocharged, air-to-air aftercooler, EPA Tier 3 emissions certified

• Exhaust pipe elbow

• Fan, hydraulic driven, electronic control, reversible

• Fuel pre-filter (10 micron) and fuel filter (2 micron)

• Grid heater

• Intake pipe with precleaner

• Water separator

ELECTRIC SYSTEM

• Alternator, 60 amp (24 V)

• Back-up alarm

• Batteries, large capacity 1000 CCA,170Ah

• Starting motor, 5.5 kW

POWER TRAIN AND CONTROLS

• Brake pedal

• Counter rotation

• Electronically controlled Hydrostatic Transmission (HST) with Quick-shift and variable speed settings

• Palm Command Control System (PCCS) with electronic control for travel control

• Reverse speed presets

UNDERCARRIAGE

• Idler cushions

• Track frames

• Track roller guards, center and end section

• Sprockets, segmented type

• Track shoe assembly w/sealed and lubricated link assembly:

—D51EX-22: 510 mm 20" HD single grouser shoes PLUS

—D51PX-22: 710 mm 28" HD single grouser shoes PLUS

GUARDS AND COVERS

• Crankcase guard and underguard

• Engine hood and side panels

• ROPS/FOPS*

• Sprocket inner guard

OPERATOR ENVIRONMENT

• 12 amp (12V) power port (cab only)

• Cab seat, high back fabric, suspension type

• Canopy seat, high back vinyl, suspension type

• Cigarette lighter (24 V, cab only)

• Cup holder, lunch box holder

• Electronic monitor panel with on-board diagnostics

• Foot rests, high mounted

• Horn

• Provision for radio (cab only)

• Rearview mirror

• Seat belt, 76 mm 3" wide retractable

DOZER ASSEMBLY

• Power Angle Tilt dozer assembly, inside arms (EX: 3045 mm 10' blade,

PX: 3350 mm 11' blade)

HYDRAULICS AND CONTROLS

• Accumulator for Proportional Pressure Control (PPC)

• Hydraulics for PAT dozer

• Palm Command Control System (PCCS) with Proportional Pressure Control (PPC) for blade control

VANDALISM PROTECTION

• Filler cap locks and cover locks

• Instrument panel lock and cover

(canopy only)

OTHER STANDARD EQUIPMENT

• Grease gun holder

• Hitch, standard type

• High altitude arrangement (no fuel adjustment up to 3000 m 9,843 ft)

• KOMTRAX function Level 2+

• Lighting package - (3 front, 2 rear cab/canopy)

• Marks and plates, English

• Pullhook, front

* ROPS cab or ROPS canopy must be ordered for all machines. Cab and canopy FOPS Level 2.

ROPS/FOPS meets all OSHA/MSHA standards and regulations criteria.

Dozer assembly and rear-mounted equipment are not included in base machine price.

Optional Equipment

TRACK SHOE ASSEMBLY WITH SEALED AND LUBRICATED LINK ASSEMBLY

• D51EX-22

– 560 mm 22" single grouser, PLUS

– 510 mm 20" single grouser, PLUS

with center hole

– 560 mm 22" single grouser, PLUS

with center hole

• D51PX-22

– 720 mm 28" single grouser, PLUS

DOZER ASSEMBLY

• D51EX-22 – 3350 mm 11' blade

TRACK ROLLER GUARDS

• Track roller guards, segmented, full

length

OPERATOR ENVIRONMENT

• Cab machine

– Seat, suspension type, fabric, high back

– Seat, suspension type, fabric low back

– Seat, air suspension type, fabric high

back

• Canopy machine

– Seat, suspension type, vinyl, low back

REAR EQUIPMENT AND HYDRAULICS

• Long drawbar

• Ripper, multi-shank (D51EX-22 only)

• Rear, hydraulics

• Rescue/recovery winch

ROPS CANOPY AND ROPS CAB EQUIPMENT

• ROPS canopy with lower heater

• ROPS cab (includes air conditioner with

heater, defroster, pressurizer)

– Optional radio, AM/FM, cassette

OPERATOR ENVIRONMENT

• Forestry guards for cab and canopy

CONTROL SYSTEMS

• Komatsu Plug n Play (Topcon ready)

• Komatsu–Topcon 2D or 3D Machine

Â

Control Systems Â

Dimensions

.jpg)

Â

UNDERCARRIAGE

Â

Â

Â

Â

Â

Â

Track roller guards, center and end section

• Sprockets, segmented type

• Track shoe assembly w/sealed and lubricated link assembly:

—D51EX-22: 510 mm 20" HD single grouser shoes PLUS

—D51PX-22: 710 mm 28" HD single grouser shoes PLUSÂ

Â

STEERING

Â

Palm Command Control System (PCCS) joystick control for all directional movements. Pushing the joystick forward results in forward machine travel, while pulling it rearward reverses the machine. Simply tilt the joystick to the left or right to make a turn.

Tilting the joystick fully to the left or right activates counter-rotation.

Hydrostatic Transmission (HST) eliminates steering clutches and brakes, providing smooth powerful turns. Fully electronic control enables smooth control. The PCCS utilizes shift buttons to increase and decrease speed.

Â

Â

Â

Â

Â

Minimum turning radius:

Â

Â

Â

Â

D51EX-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.39 m 7'10"

D51PX-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.62 m 8'7"

Â

As measured by track marks on the ground at pivot turn.

.jpg) Â

.jpg)

D51EX-22

D51EX-22