PRODUCTS

We know the success of our business depends directly from you. Thinking that we created this area so you can have quick access to all of your equipment. For more information, please contact us by CLICKING HERE.

D51EX-22

Maintenance Features

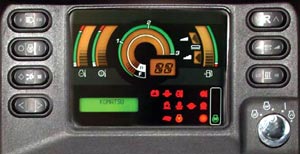

New Monitor with Self-diagnostic Function

Daily Checks

All daily checks can be performed efficiently at ground level.

Remote Grease Points

Remote grease points facilitate lubrication of the C-frame pivots, equalizer center pins, and angle cylinder bearing.

Hydraulically-driven Swing-up Fan

The D51-22 utilizes a swing-up fan with a gas strut-assisted lift locking system to provide easy access to the (side-byside) radiator, oil cooler, and charge air cooler. The swing-up feature makes it easier to access cooling cores. The hydraulic fan has a ‚Äúcleaning‚ÄĚ mode. The fan rotates in the reverse direction and helps to clear off objects in front of the cooling areas. The fan is protected by thick steel louvers and an additional fan screen for added durability.¬†

Adjustment-free Parking Disc Brake

An adjustment-free spring-applied hydraulic-release wet parking brake is located in each final drive. Dynamic HST braking is used until the machine stops moving, then the parking brake engages, minimizing wear.

Segmented Sprocket Teeth

This design reduces servicing time as compared to solid sprocket designs. Each of the nine bolt-on segments can be replaced without splitting the track.

Best viewed in 1024x768

D51EX-22

D51EX-22